|

|

| Colour Coated Roof Sheets | ||||||||||

|

||||||||||

| Products Being Manufactured | ||||||||||

|

||||||||||

| Standard Specs | ||||||||||

| Substrate • GI – as per IS 513:1994 • GL – as per IS ASTM A653/A 653M - 02 • AL – as per grade 3105 / 8011 Coating • Zn coating as per IS 277-1992 • Zn/Al coating as per ASTM A653/A 653M - 02 • Organic coating as per guidance of IS 14246:1995 Test methodologies for finished products • IS 14246:1995 Supply of Material • IS 8910:1978 |

||||||||||

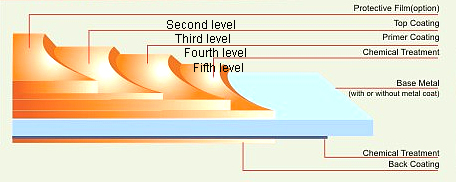

| Cross sectional view | ||||||||||

|

||||||||||

| Salient Points » Multiple layers of protection ensures very high service Life ( almost 4 times normal GI sheets in similar conditions) » Colourful top coating ensures very high aesthetic apeal » Optional Guard film ensures protection during handling/ forming. » Service back coat in greys for better light dispersion and for soothing effect on eyes. |

||||||||||

| Standard colours available | ||||||||||

| RMP / SMP: RAL1013 / RAL1014 /RAL1015 RAL1019 /RAL5012 /RAL6021 /RAL7004 RAL7005/RAL7010/RAL7011/RAL7012 RAL7023/RAL7030/RAL7032/RAL7035 RAL7038/RAL8016 /RAL8017/RAL9002 RAL9003/RAL9010 Most common shades are 9002 / 5012 /6002 / 3001 / appliance white. |

||||||||||

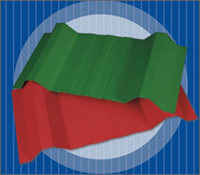

| Salient features of our profile | ||||||||||

» Best balance between coverage and strength (1000mm covered width, highest Ixx in the category) » High ribbed profile for better support on longer spans » 32mm trapezoidal crest for adequate drainage and aesthetic appeal » Hexagonal trapezoid for best load distribution » Anti capillary groove to ensure zero leakage as a result of capillary action » Scientific design for usage in high wind load areas also » Suitable for Roofing/ Cladding/ Barricading and other applications |

||||||||||

|

||||||||||

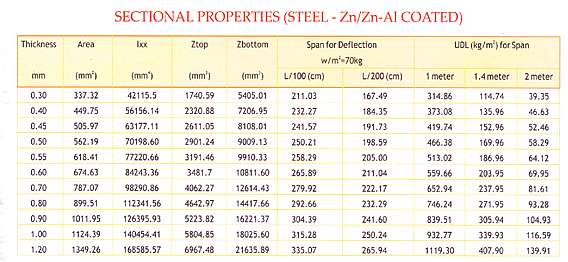

| Sectional Properties of profile | ||||||||||

|

||||||||||

| Right Product for right Applications | ||||||||||

» Choose correct material / thickness/profile /coating for all application » Thickness : 0.5mm TCT for general use, for long spans, use higher thickness » Manaksia 1000 Profile suited to handle most applications , only under very special requirement of very high wind loads( severe cyclone areas only) we recommend higher corrugation profiles » Where interlocking formation is needed we recommend softer material like normal PPGI / PPAL |

||||||||||

| Dos of fixing | ||||||||||

| » Do check the delivery to make sure you have the right product, delivered in prime condition. » Do arrange for suitable dry storage if the material is not going to be used immediately. » Do ensure the appropriate fasteners are selected for the environment. » Do cut with shears or snips. » Do remove swarf from the job as the work progresses, or at least at the end of each day. » Do wear clean, flat, rubber-soled footwear. » Do lift sheets onto the job, rather than drag them. » Strictly avoid surface abrasion by walking / rubbing/dragging/etc over the coated area . It will damage the coatings. |

|

|||||||||